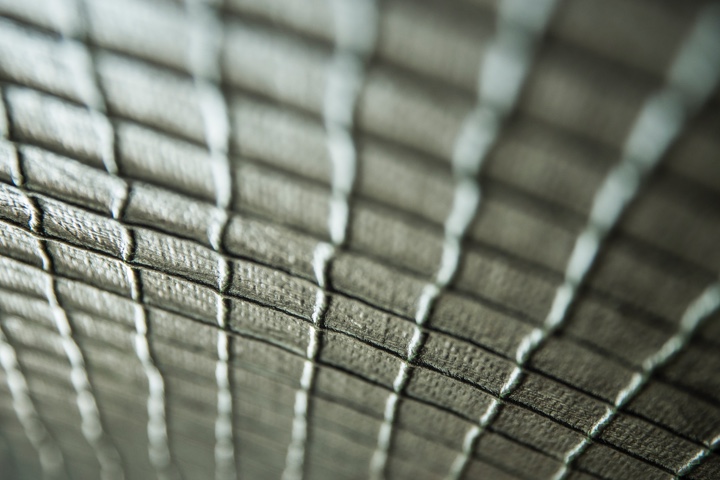

The award-winning powerRibs™ technology is an extremely lightweight, high performance natural fibre reinforcement grid.

Inspired by leaf veins, powerRibs™ add maximal stiffness at minimal weight by creating a 3D structure on one side of a thin walled shell element. This enables using less base material, decreasing weight, costs and consumables in production. The proprietary technology is perfect for high-performance applications such as replacing or reinforcing carbon fibres in motorsport bodywork or decreasing weight in automotive interior panels.

powerRibs™ can be used in different manufacturing scenarios:

The flax fibre quality, yarn thickness and twist are all highly engineered for optimal mechanical properties in the final composite part. The fibres are specifically treated to optimise the fibre-matrix interface. We use European flax and the fibremix is thoroughly controlled for consistent quality over time.

powerRibs™ can triple the flexural bending stiffness and thereby decrease both material use and weight, while improving vibration damping. When powerRibs™ are combined with our ampliTex™ technical fabrics it creates a full natural fibre layup that matches the performance of carbon fibres. powerRibs™ also work excellently to reinforce carbon fibres and glass fibres.