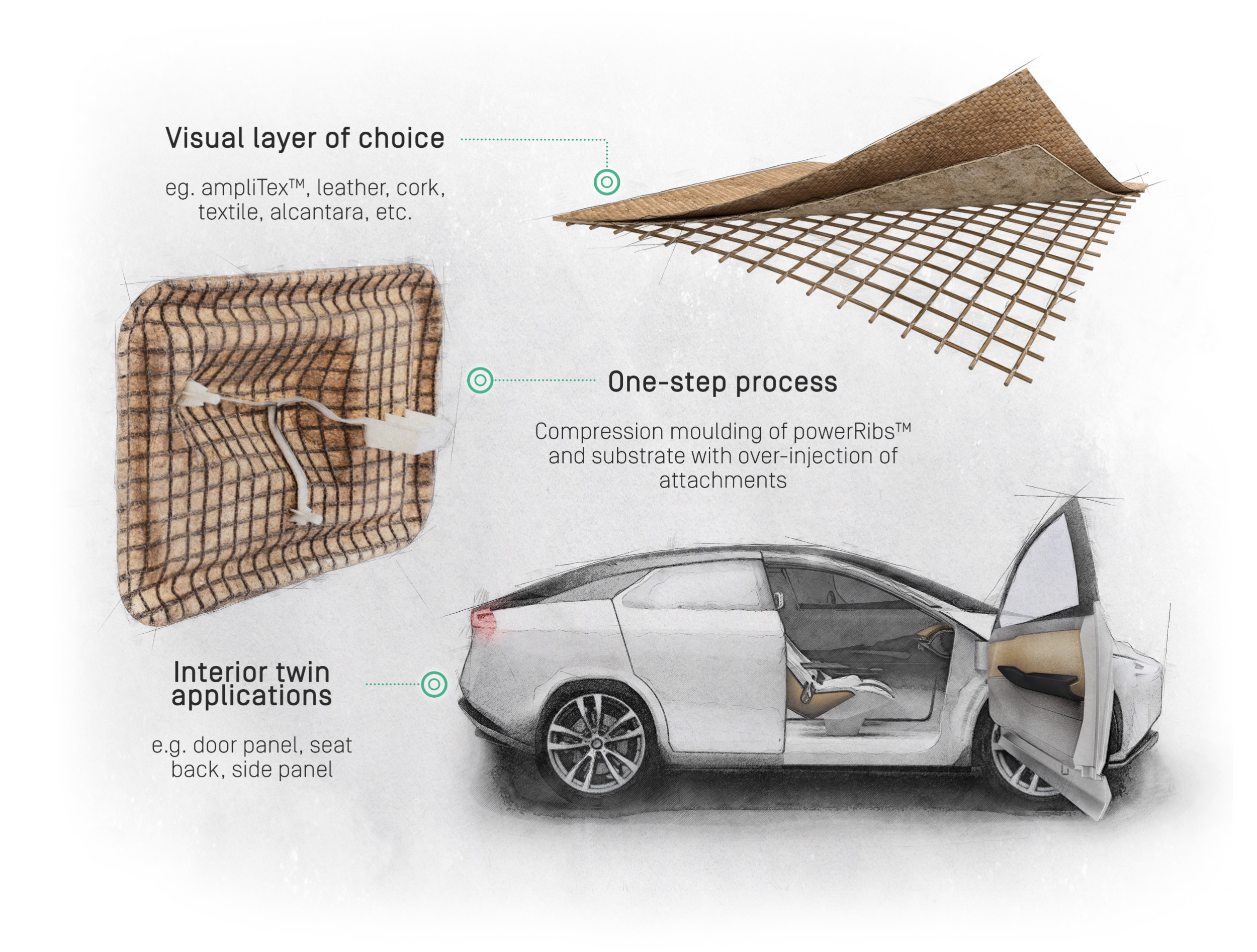

There is an ongoing revolution towards cleaner mobility for the future. Bcomp’s solutions for sustainable lightweighting with thermoplastic powerRibs™ can cut weight by up to 50% and reduce plastic by up to 70% in interior panels. Thereby both the impact of materials used, and fuel consumption can be reduced. The solution is cost-efficient and can be seamlessly integrated into high-speed production lines. ampliTex™ technical fabrics enable novel design options, creating a functional and visual layer in one.

High performance

Reduce weight by up to 50% at equivalent stiffness

Improved safety

Ductile fracture behaviour and no sharp edges

More sustainable

Up to 70% less plastic, energy recovery recycling

Improved cost efficiency

Integrate in high-speed production lines with one-step back injection

Bcomp’s solution for sustainable lightweighting in interior panels with thermoplastic powerRibs™ for large scale production won the JEC Future of Composites in Transportation 2018 Innovation Award in the “sustainability” category together with Persico.

Implementation projects are ongoing with multiple OEMs for interiors in serial production models.

In 2018, the solution was used to reinforce recycled ocean plastic in the Volvo Cars Recycled Plastics Demonstrator Vehicle presented in connection to the Volvo Ocean Race.

In 2020, Polestar announced a partnership with Bcomp for the development of more sustainable interior panels in future production models, as well as for visual panels in the Polestar Precept. The Precept was later announced to be a production model, thanks to the positive response from the market.

In 2021, Volvo Cars presented the Volvo Cars Concept Recharge, using Bcomp’s natural fibre composites for the lower storage areas, back of the headrest and the footrest, as well as for the front and rear bumpers and sill moldings of the exterior.

© Polestar

To reduce weight, material use and environmental impact, the Polestar Precept uses Bcomp’s powerRibs™ and ampliTex™ natural fibre composites for a wide range of interior panels including the seat back. In addition, the ampliTex™ enables unique design opportunities for visual surfaces and is spectacularly backlit in the Precept to highlight the design features. According to Polestar, the ambition is to bring much of these sustainable solutions into production.

Polestar Precept

© Volvo Car Group

Volvo Cars has announced the application of Bcomp's natural fibre composite technology, ampliTex™, in the new Volvo EX30. This landmark project will see Bcomp’s flax fibre composites offered as an optional trim for the dashboard, and doors of the EX30. The collaboration follows Volvo Cars Tech Fund’s Series B investment in Bcomp last year. The highly innovative Volvo EX30 is an all-electric small SUV that combines safety, sustainability, cutting-edge tech, and Scandinavian design. Drivers can choose from four distinct interior ‘rooms’, two of which embrace the natural aesthetic of ampliTex™ trim panels: the Mist and Pine rooms.

Volvo Cars EX30 door panel

Bcomp and Persico Automotive received the JEC Future of Composites in Transportation 2018 Innovation Award for the production technology that enables the use of high-performance powerRibs™ natural fibre reinforcements on an industrial scale.

Award-winning production technology

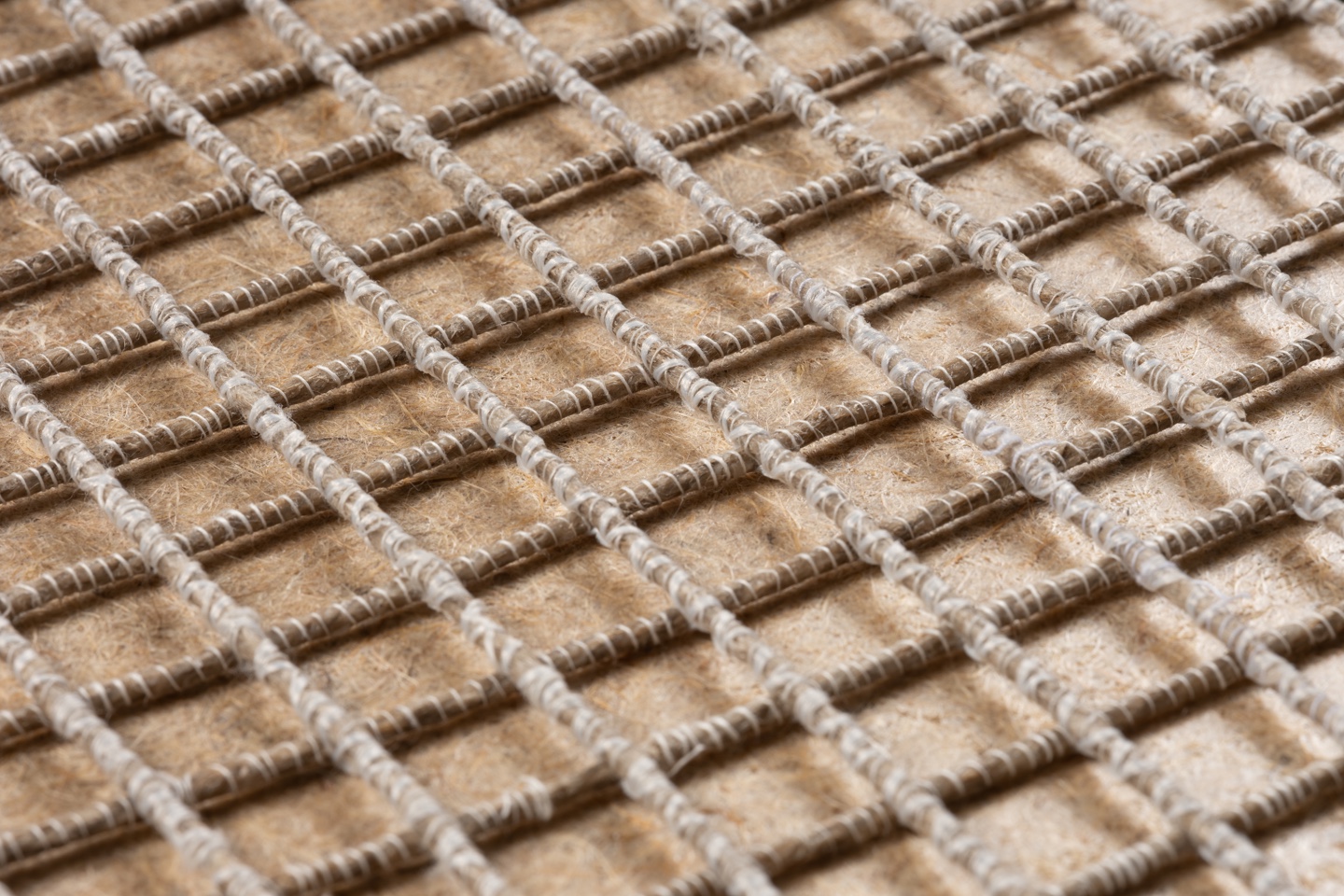

powerRibs™ and ampliTex™ are made from flax fibres that grow naturally in Europe without competing with food crops. By optimising the properties of the fibres mechanically and through fabric architecture, less material is used. At the end of their life, parts can be ground down into a new base material, or used for thermal energy recovery without residual waste in the standard waste management system.

Thermoplastic parts are made using one-step back-injection, which compression moulds powerRibs™ with a base layer NFPP fleece, ampliTex™ or other decorative visual layer, attachment points and punching in the same step. With the award-winning employment of a soft silicone layer on the b-side in the compression moulding tool, the full stiffening potential of the powerRibs™ preform is reached and maintained. Our team of specialised engineers support clients all the way to their finalised part.

The powerRibs™ + NFPP solution can be easily wrapped in any traditional coverstock material, while Bcomp also offers a range of ampliTex™ technical fabrics for additional stiffness and novel design options, that can be integrated in the production to complete the solution.

With the ampliTex™ and powerRibs™ product ranges, we offer solutions for sustainable lightweighting from sports to space.

The ampliTex™ and powerRibs™ product ranges of natural fibre reinforcements for sustainable lightweighting.